The first industrial revolution started in roughly the middle of the 18th century and ran for about a hundred years. The key elements of that revolution were the transition from hand-made to machine-crafted goods (especially textiles) and water and later steam-powered machinery. The second industrial revolution started around the mid-1800s and lasted into the first part of the 20th century. This revolution was characterized by the advent of electrical power and early communications systems such as the telegraph and telephone. The third revolution is the dawn of the “digital age” in the mid to late 1900s, driven by solid state electronics, computers, and digital communications systems such as the internet.

Now we’re entering what many pundits are calling the fourth industrial revolution, or “Industry 4.0” as it is becoming known. Among its diverse products are leading edge biotechnology and autonomous vehicles, but the area we are particularly interested in involves the intersection of advanced sensors, automation, robotics, AI and IoT. Industry 4.0 will bring us a new era of “smart machines” which will constantly monitor themselves and their environment, and communicate with each other, humans, and local and cloud-based computing and information resources.

One form of monitoring is known as “predictive maintenance.” In this case, the smart machines will dramatically increase productivity and reduce costs by running at peak efficiency and alerting technicians to possible maintenance issues well ahead of any actual failure. In some cases the machines will be able to maintain themselves or call upon other machines for fully automated maintenance. They will also use vision and other sensor analysis to make intelligent product/machine placement, orientation, fabrication, and sorting decisions. Ultimately they’ll also communicate with factory order systems and use AI and “big data” analysis to optimize production for the company.

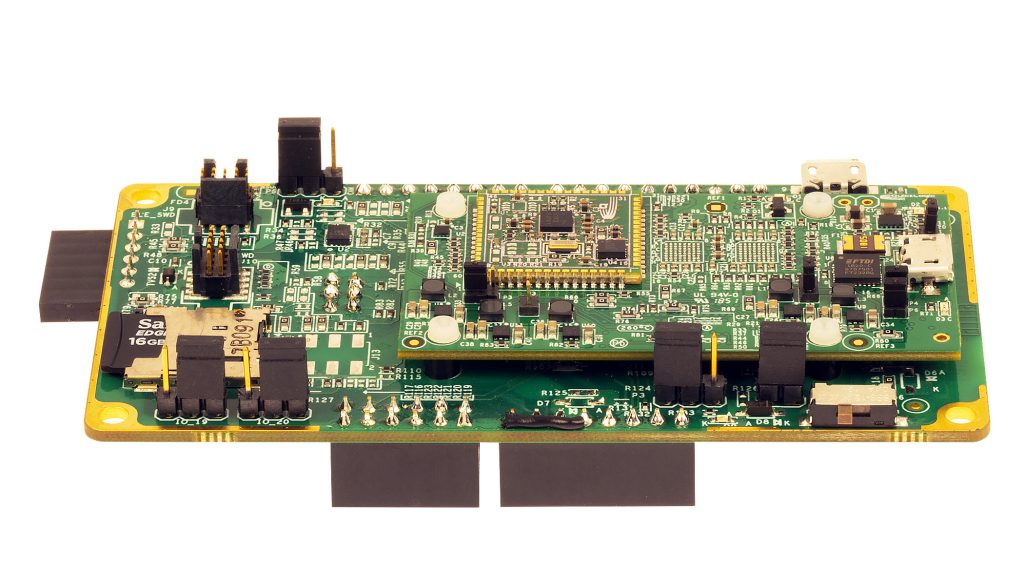

Here at QuickLogic we are doing our part to drive this fourth industrial revolution. We just introduced our new QuickAI EOS S3AI HDK, an easy to use development platform designed to help with evaluation of QuickLogic’s Time-Series AI solution. It also links directly with the Data Analytics Toolkit from SensiML (a company that we recently acquired) in order to collect data and develop AI models, algorithms and new classifiers. Together the elements of this platform provide a complete solution for local AI-based IoT – perfect for Industry 4.0 applications. A key benefit of the QuickLogic solution is that it provides a quick and easy way for developers to bring the power of AI all the way to the endpoint, allowing local decision making which reduces latency, power consumption, and system costs.

Developers building Industry 4.0 applications now have a complete HDK which includes the platform, algorithms and software tools they need to add sophisticated AI technology to their industrial machinery without needing large teams of data scientists or firmware engineers. This approach will accelerate the adoption of AI at the endpoint for manufacturing and other industrial processes – bringing the vast promise of this fourth wave of industrial revolution to all of us consumers so much sooner.